Why Does Your Business Need Chemical Plant Calibration Software?

Being an innovative business leader, you must have heard numerous times that equipment calibration in SAP is highly effective. So, if the question, why you need to invest in chemical plant calibration software is constantly bugging you, the answer is pretty simple—

To reduce risk, boost document processing time, and quickly analyze data for better decision-making, you need chemical plant calibration software. Due to these core benefits of equipment calibration software in SAP, the calibration management software market size is projected to reach $100.84 million between 2020-2024.

That’s indeed superb growth! However, you should switch to calibration software today if you are still stuck with manual documentation and data analysis processes. This one move can help your business a lot. Let’s find out why calibration management software is a must for your business growth.

9 Reasons to Use Chemical Plant Calibration Software

In a manual spreadsheet formation, the chances of human errors are between 18% and 40%. On the contrary, human error probability in the complex spreadsheet is 100%. Here, if you use equipment calibration in SAP, the human error risk can be reduced to nil. That’s not only it; calibration software can help with:

Swift Planning and Scheduling

If you have a large chemical plant, planning and setting a schedule for every calibration engineer must be very time-consuming for you. But, thanks to chemical plant calibration software you can define a schedule and plan of action for every calibration engineer within a platform. The software lets you alert the right person for the job on time. Within the platform, a task assignment process can be performed, which will save lots of time.

Easy to Update

The equipment calibration in SAP is used due to its easy functionality. You can easily pollute the tool with your spreadsheet data. From the standard excel spreadsheet, you can seamlessly transfer data to the platform. When the human data entry process is eliminated, a huge amount of errors can be avoided. This will eventually improve the quality and efficiency of the decision-making process.

Meet Compliance

With the help of software, you can effortlessly meet all the legal compliance. A good chemical plant calibration software can help you meet FDA, ISO, GAMP along with 21CFR Part 11 compliance. When your documents are prepared according to the latest compliance, the risk level will dramatically reduce in your operations.

Paperless Calibration

The software helps you to make your entire calibration process paperless. With the paperless calibration process, you can save data processing time and multiple other risks. For instance, if you want to print the results of your entire calibration task, it is impossible with the manual process. But, if you use software, with just a click, you can print out your calibration results. Additionally, you digitally share results via email with all stakeholders.

Data Compilation

Over the years, different calibration writers have created reports for your company. And, if you wish to retrieve old files for reference purposes, managing and finding paper-based files is not at all an easy process. However, calibration management software can easily preserve your years of historical data that you can retrieve with a flicker of your finger.

Easily Accessible

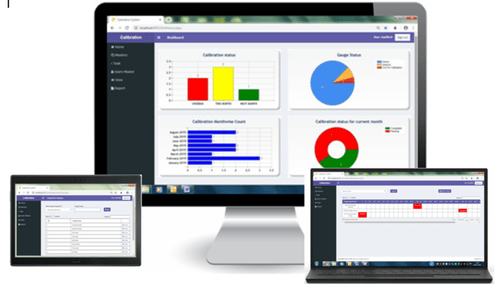

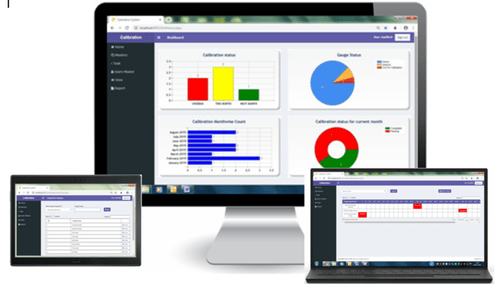

Companies with multiple branches or remote technicians can get cloud-based chemical plant calibration software. The cloud-based calibration software is easy to access from anywhere and anytime. Your technicians can quickly access information even when they aren’t present on the premises.

Highly Secure

Manually generated calibration report files are prone to physical damage and theft. Once physical files are damaged, there’s no way to retrieve them back. Luckily, calibration software offers high-end security against internal as well as external vulnerabilities. If you want highly secured calibration management software, you can opt for an on-premises one.

Mobile-Enabled Software

Nowadays, equipment calibration in SAP is also designed to support mobile interfaces. That means you can create, organize and access your calibration results from your mobile devices. You can click open calibration software on your mobile device and constantly monitor your data.

Training and Documentation

The calibration software developers produce detailed documentation and training modules supporting the software. This way, you can easily train your new employees to use the calibration software. Additionally, calibration software is designed for moderate-level users so you can quickly train your employees to use it.

Where to Find the Best Chemical Plant Calibration Software?

After reading all the benefits of equipment calibration in SAP, you must be eager to get calibration software for your firm. To do so, you should drop by the Prime Technologies website anytime. We offer a proven calibration management software to manage your assets for validation, calibration, and maintenance. Thus, to save time, increase productivity, improve efficiency and regulate compliance, request the best on-premises calibration software for your company now!